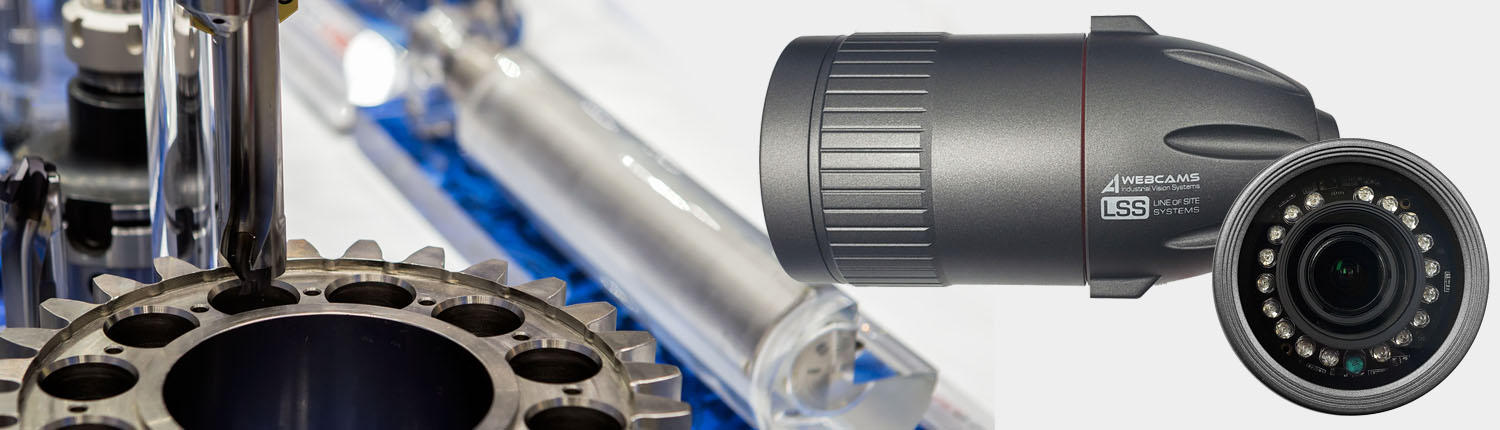

Assembly

Streamline Processes, Mitigate Rejections & Recalls, Advanced Throughput

Packaging

Package Faster, Function Efficiently, Optimize Quality, Monitor and Capture Every Line Segment

Logistics

Drive Down Costs, Hold Suppliers Accountable, Enhance Automation, Increase Efficiencies

How we can help you!

Our Industrial Vision Systems are designed to improve the Overall Equipment Effectiveness (OEE) of any manufacturing production line. Enabling on the spot root cause analysis and the ability to track and visualize your downtime events, you can save on product waste, decrease product turnover times, and increase revenue.