Product Applications

Beverage

Troubleshooting the infeed of a filler, ensuring the proper setup of a seamer, or diagnosing a case packer that jams every two hours is nearly impossible when you are running flat out at 1,500+ units per minute.

Our high speed video provides a detailed view into this high speed world without slowing down production.

Built to withstand moisture and the conditions often found along a beverage line, our products are designed to operate in this environment.

.

Converting Process

Converting lines handle continuous, high-speed processing of web materials into finished products, where even brief disturbances can cause costly defects or downtime.

LineSpex empowers teams with real-time visibility into critical zones like unwinds, nips, slitters, perforators, and die-cut stations. Our high-frame-rate cameras and intuitive playback tools make it easy to spot tension shifts, registration errors, material jams, or component misfeeds. Whether you’re fine-tuning changeovers or chasing down intermittent faults, LineSpex helps ensure your converting process stays consistent, efficient, and under control.

.

Feminine Care

Feminine care lines often run at high speeds with intricate material handling across multiple web layers, making visibility into minor faults a major challenge.

With LineSpex, teams can monitor key process points like pad forming, folding stations, adhesive application, and final wrapping. Our high-resolution cameras and real-time review tools allow for quick diagnosis of skewed product alignment, transfer losses, or web tension inconsistencies. Whether you’re troubleshooting recurring micro-stoppages or optimizing machine timing, LineSpex provides the insights needed to act fast and maintain performance.

Food

With the need for perfect quality and low cost production, packaging of food products can be particularly difficult.

Operators can see jams in slow motion and instantly determine whether environmental issues (temperature, etc.), line setups, or material defects are the root cause.

Machine Tools

Machine tools wear over time and raw materials are not perfect. Our high speed cameras can stop the action so you can see a sharp image of the operation. Then, operators can use the easy-to-understand interface to step frame-by-frame through the job to see how the tool, design and material are performing.

Packaging & Palletizers

Ensuring that your deliveries are always correctly counted and packed is important to keeping your production line operation efficiency at its best. Our systems help with root cause analysis so you can streamline your packaging and palletizing operation to be simpler, faster and more efficient.

With A1Webcams, we can help eliminate downtime by providing a close look at each step and giving valuable feedback for troubleshooting and resolving issues.

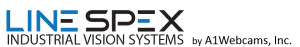

Pharmaceutical

Characterized by stringent requirements and high per-unit cost, pharmaceutical manufacturing has its own unique set of challenges. Our solutions allow you to capture, replay, distribute, analyze and permanently eliminate the root cause of production problems.

Pulp and Paper

Paper making is a highly sophisticated process involving several steps to turn wood logs into paper products. Opportunities for inconsistencies across any number of stages can lead to downtime or production waste.

With A1Webcams, we can help eliminate downtime by providing a close look at each step and giving valuable feedback for troubleshooting and resolving issues.

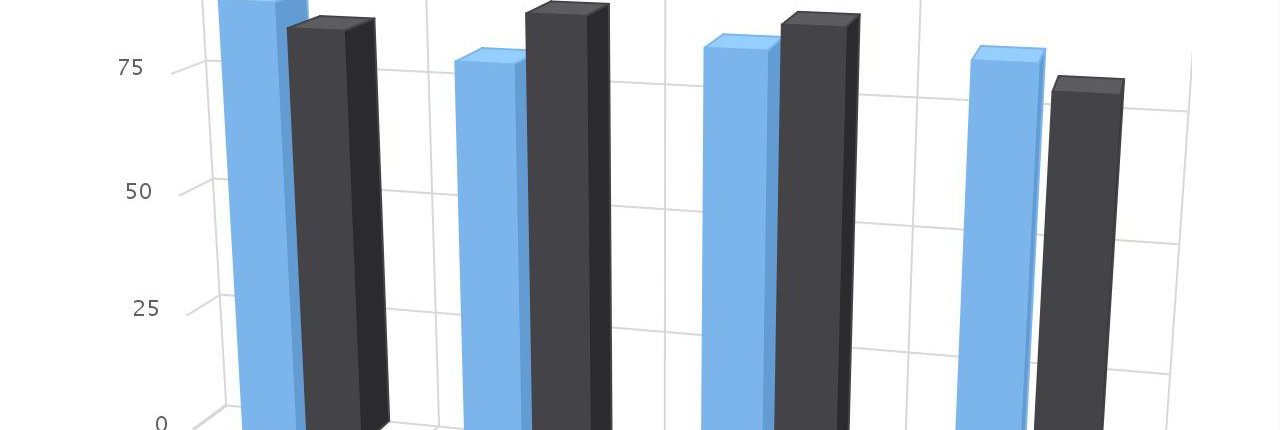

Improving OEE

One of the major goals of OEE (Overall Equipment Effectiveness) programs is to reduce and/or eliminate what are called the Six Big Losses – the most common causes of efficiency loss in manufacturing.

The Line of Site System is a continuous monitoring solution that addresses all Six Big Losses. LSS kits are an excellent countermeasure tool to be used in addressing the Six Big Losses and have proven to be especially beneficial in root cause analysis, improving line efficiency, elimination of “short-stops,” and line speed increases.

Plants have reported the technology paid for itself within the first few weeks of use on the plant floor. The vast majority of customers will no longer operate without LSS Continuous Monitoring Solution.