Archive for year: 2019

Plant Manager’s Problem:

Every year manufacturers worldwide lose millions of dollars due to unplanned production line disruptions and failures. Even with necessary preventative measures and predictive maintenance in place, unplanned downtimes are inevitable. The way to minimize loses associated with the downtime events is simple, faster root cause analysis.

Our Solution:

With our hardware integrated with downtime software, we can guarantee faster root cause analysis resulting in increased efficiency of the production process by decreasing overall time during unplanned production stops. Our intelligent downtime system integrates with the machines’ event tags/fault codes to identify failures and provide high definition video footage of how the failure happened.

Linespex and Fortech hope to see you this week at the Las Vegas Pack Expo on September 23-25.

We invite you to stop by our booth and see how you can significantly improve the efficiency of your manufacturing lines. Our affordable systems and software have the ability to capture unparalleled data leading to accurate identification of costly downtime.

BOOTHS 8292 and 8293

For free registration, enter comp code 41P43 and the registration fee will be waived prior to your checkout.

For Additional information:

Industrial Vision Systems

Marvin Kiwan

marvin.kiwan@linespex.com

714.688.7986 EXT 102

www.a1webcams.com

Our Industrial Vision Systems improve the productivity and quality of the production line. Our affordable production line monitoring systems are most valuable when used to enhance production efficiencies and reduce product waste. Immediate on the spot root cause analysis and the ability to track and visualize downtime events becomes effortless. Our systems improve quality and productivity, while driving down manufacturing costs which ultimately could have been costly.

Problem statement: Inability to see incidents in order to understand how to fix and determine root cause.

Objective: Develop a low-cost system that allows operators and management to increase visibility and problem-solve faster.

Result: They were able to identify maintenance issues immediately with the LineSpex System by reviewing live footage rather than having to replicate the fault; saving blocked product due to new sightline and rewind capabilities.

For downtime, knowing when, where, and how downtime occurs is essential to knowing how to prevent it. An early step toward reducing unexpected production backups and downtime can be achieved. By using our LineSpex Industrial Vision System, you will be able to carefully and accurately track when and where downtime occurs.

Wasted and recalled products are unfortunate consequences of a manufacturing process that is not running as efficiently as it could be. By enhancing quality, facilities can drastically reduce these outcomes, which accelerates output and increases customer satisfaction.

One of the best ways to minimize waste and to optimize real time quality data is from our Industrial Vision Systems. We have taken the guesswork out of unknown production stops, by enabling on the spot root cause analysis and the ability to track and visualize your downtime events. That way you can save on product waste, decrease product turnover rates and overall increase revenue.

Our Industrial Vision Systems are being used in multiple facilities throughout the United States that have won awards across several categories, including environmental sustainability, diversity and inclusion, safety and innovation.

Our Line of Site System is a continuous monitoring solution that addresses all Six Big Losses. LSS kits are an excellent countermeasure tool to be used in addressing the Six Big Losses and have proven to be especially beneficial in root cause analysis, improving line efficiency, elimination of “shortstops,” and line speed increases. Plants have reported the technology paid for itself within the first few weeks of use on the plant floor. The vast majority of customers will no longer operate without LSS Continuous Monitoring Solution

Plants have reported the technology paid for itself within the first few weeks of use on the plant floor. The vast majority of customers will no longer operate without LSS Continuous Monitoring Solution.

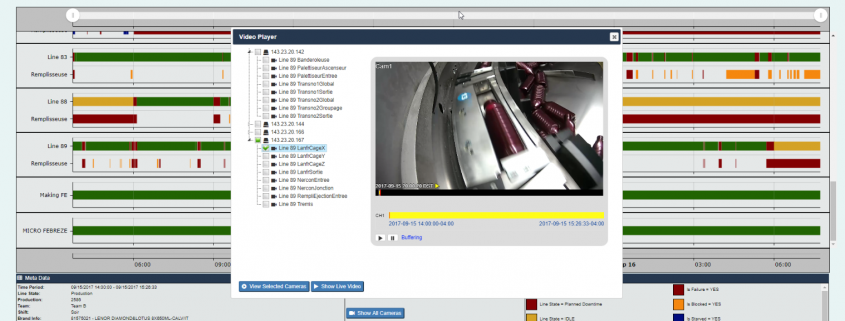

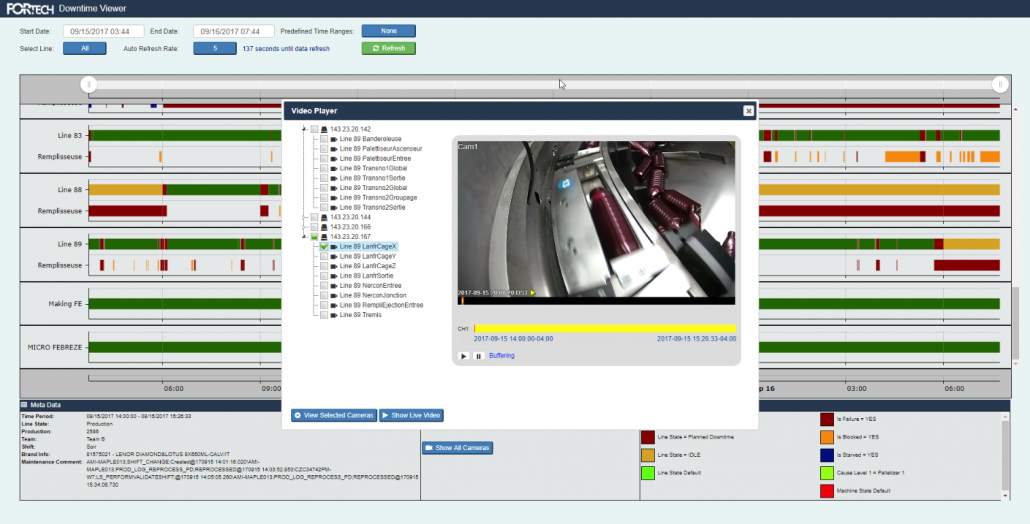

DownTime Viewer + Video

Integrated Machine Vision

Brief Description

The MAPLE Suite Downtime Viewer (DTV) and video is a system that was developed by Fortech that integrates with the LineSpex machine vision system to that help ensure quality and efficiency are built into the manufacturing process and are proactively and systematically enforced.

The Downtime Viewer and video system can connect multiple plants, sites and live production information, and integrate with equipment, controllers and enterprise business applications. The result is visibility, control and optimization of production and processes across the enterprise. DTV operates alongside most existing MES/MOM systems and integrates with existing fault code / event tag data.

Key Features

- Automated capture and tracking of equipment downtimes and production

- Web-based KPI dashboard and ad-hoc reporting

- Utilization of emerging technologies like video, mobile and web

- User interface optimized for touch screen and efficient operator usability

- Integration with applications and equipment throughout the enterprise

- Highly configurable and adaptable to a multitude of operations

Benefits

- Make fact-based operational and strategic decisions

- Continuously improve product quality and new designs

- Proactively and systematically standardize and enforce processes across all sites

- Gain real-time visibility and control across the manufacturing supply chain

- Accelerate trace analysis, root cause diagnosis and issue resolution

- Lower cost of good quality

For questions or more information contact

Marvin Kiwan at 714-688-7986 EXT 102 or marvin.kiwan@linespex.com

Production line managers, are you experiencing bottlenecks and efficiency issues on your production line? No matter the situation real time problem solving is crucial to company operations, especially in a manufacturing organization. Unplanned stops are costly to any business and being able to create a leaner more efficient operation lowers the bottom line and increases profits.

With the use of our Industrial Vision Systems coupled with our partner Fortech’s Downtime Viewer there are given intelligent eyes on the line. Allowing manufacturers to take control of their own success. They are able to better control the quality of product, machine maintenance, and work with machine manufactures accountable for failures.

“Lean, green and clean manufacturing”

“Green” manufacturing is now becoming the new standard in the manufacturing industry, saving money and time. “Green” manufacturing offers extensive advances in efficiency and productivity without the drawbacks of waste and pollution.

There are an immense amount of benefits manufacturing plants can gain by implementing “green” practices in their facilities. By increasing overall productivity and efficiencies while reducing unplanned downtimes caused by ineffective machinery. they are able to reduce the numerous hours trying to pin point exactly where on the production line the issue had occurred, we can help you save time, money and waste.

With the use of our Industrial Vision Systems, you can be on the way to creating a more efficient facility. Our systems will integrate with your current MES systems to catch unplanned downtime on the production line, increase the efficiency of the production process by decreasing unplanned production stops and increasing overall efficiency throughout the whole manufacturing process.

New facilities are being built with a more efficient manufacturing process in mind. While the older facilities can benefit from upgrading to a more sustainable and efficient solution.

Linespex.com

Linespex.com